A sphere cutter is easy to make if you have a spindle such as on a flat lap.

Pick up a (2 inch) pipe plug, the kind with a square bolt head on the end, at your hardware store. Drill and tap thru the center of the square bolt head so it will fit on your (vertical preferred) spindle. You need to be pretty accurate about being on center. Also pick up a brass 90 degree elbow of about the same size (its easier to hold than a straight pipe).

Cut a cube of rock and then trim off all the corners with your saw. Use a coarse grinding wheel to smooth it more towards a sphere. Put your lumpy ball on the plug (that is on the spindle, bolt end down and round edge, which should be cup shaped, up) and hold it down with one end of the brass elbow. The two pipe ends should make a 15 to 30 degree angle - you'll quickly find the right angle, and rock it a bit as it works. I find a lower speed works better.

Turn it on and start applying coarse loose carbo (tumbling grit) in a water slurry (you can pour thru the elbow) and wear goggles to protect from splash. Turn it off before removing the top pipe or the ball may fly (or pick up the ball off the rotating bottom pipe end, but be careful).

Work thru the grits once it is round, cleaning the pipe and plug well between them (the pipes can imbed grit, so a steel brush helps).

Glue on felt or leather circles to polish, or put the ball in your tumbler with a handful of garnets the size of peas and pre-polish/polish it that way. About $10.00, including the tap to put the threads in the hole and a bit to drill it, and maybe an hour of time. Works great.

Here are a few contrived photographs (the sphere was already cut) showing some of the details of the process. I'm right-handed but was holding the camera in that hand, so you will see my left hand; pretend the pictures were reversed.

And a few comments from correspondence about this webpage topic...

> > Actually, sphere cutting is non-obvious until you've done it. I don't

> > have a picture handy so I'll try the 1,000 words (you may have to round

> > up ;-)...

> >

> > The cup the sphere sits on is on a vertical shaft that is rotating. This

> > causes the sphere to rotate along with it - the 'equator' of the sphere

> > is in a plane that is parallel to the floor.

> >

> > The 'elbow' on top of the sphere is tipped off vertical. Friction with

> > the elbow tries to pull the rotation of the sphere into an axis running

> > thru the cylinder touching the sphere from the elbow. The equator of the

> > sphere wobbles between the two axis randomly so the sphere rotates on

> > two axis bringing every part of the sphere to one of the two cylinder

> > ends (the cup and the elbow).

> >

> > The cutting action occurs from grit getting between the two cylinder

> > ends and the surface of the sphere. I hope this drawing comes thru...

> >

> > // The elbow (or at least the end of it)

> > () The sphere

> > || The spindle/cup

> >

> > I'll try to get a picture posted of my setup in operation and let you

> > know when it is on the website (maybe this weekend). I hope this

> > additional description helps. I agree I need to make my writeup clearer.

> >

> > BTW, Stupid questions are the ones you don't ask when something is not

> > clear.

A more conventional sphere cutter has three heads 120 degrees apart, and a motor on each head. You can read about making and using one of these in Rock & Gem Magazine's April and May 2004 issues. I've personally seen Jim Perkins' machine work, and the plans are clean. But you will have to find your own copies of the magazine.

You can find more information about cutting spheres from Wes Lingerfelt's FAQ at www.sphereheaven.com (in the Store, under Equipment, at the bottom). BTW, I always recommend looking closely at manufactured equipment before building; if you want diamond heads for your homemade sphere cutter you need to see what Wes is offering, whether you build or buy, as it should give you ideas.

{Standard Disclaimer: Opinions here are my own as a hobbiest -- I have no economic interest in any dealers referenced on this website other than as a customer.]

Let me offer you three methods that can be used to drill holes in stones or glass.

A) Get a carbide drill of the right size, and be very, very patient when drilling.

B) Get a set of diamond burrs for a MotoTool, use lots of water or saw coolent (not usually mentioned) so the burr of the correct size does not overheat (which destroys it), and be patient when drilling.

C) Find a finishing nail with a head just a little smaller than the

hole needed. Use a triangle file or hacksaw to put a X on the head. Put

it in your drill press (you can use a hand drill, or even a bow-drill,

but its a lot harder to keep the nail drill bit straight) using the head

you Xed as the tip of the bit. Secure the stone to something (dop wax,

pitch, plaster) so you can fasten it down to the drill press table

(workbench if by hand). Make a small dam of wax around where the hole is

to go.

Fill the enclosed area with watered loose carbo grit (the bigger the

hole, the coarser the grade; try 200-400 range for a 3/32 hole) in water

and refresh grit periodically. Be very patient when drilling. For any

larger holes (3/32 is right on the edge of nail and pipe) you might want

to use a length of pipe with notches cut into the end and cut out a

cylinder. A (trimmed) tin can fastened to a bolt with washers, so it can

be closely centered, (about twice the length of the thickness to be cut)

with (possibly) notched cutting edge (1/3 the length of the can), can be used to

cut larger plugs this way. A jig to hold the can steady on the rock (or glass) helps in getting it started - it will ride in the cut groove after that. A drill press is easier than a hand drill.

I recently had to cut some circles out of glass and used a soup can and a thrown-together jig to cut through single thickness glass in about 15 minutes a circle. Here are a few pictures taken during the project. It works the same way with rock slabs, but usually takes a little longer. The carbo I used was collected from tumbling loads for recycle and was a mix of all grades.

Good luck on your holes. I recommend you try glass for practice before moving to that special specimen. Its easy once you get the hang of it. BTW, Daniel Lopacki has some good tips on drilling stone you might want to review.

I was unable to locate any plans on the web for making your own tumbler, so I posted this to respond to a commonly asked question.

Our goal is to rotate a cylindrical container containing rocks, water, and grit/polish (working thru a series of grits/polishes with cleaning between) to bring the rocks to a high polish. Rubber lined containers are probably the best. Plastic can be used. With metal containers you probably need one for each grade of grit/polish to avoid grit/polish grade contamination.

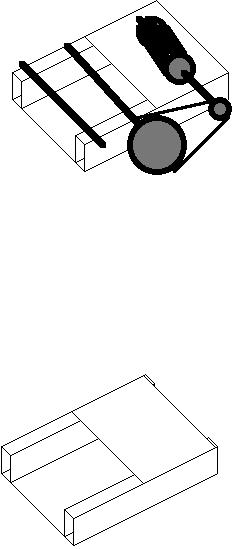

The classic tumbler rests the barrel on two revolving shafts, one driven, one free. The rotation of the driven shaft revolves the barrel, which then drives the free shaft. A motor is pulley/belt connected to the driven shaft. The power train - motor RPM, motor pulley/shaft pulley ratio, shaft to barrel ratio - causes the barrel to rotate at an appropriate speed; a four inch barrel rotates 50-100 RPM, bigger barrels more slowly. I suggest keeping towards the slower end of the range.

Start by finding a barrel. The widest part of the outside needs to make a cylinder. Narrower in the middle (wider top and bottom) is ok if it is the same size cylinder at the ends.

Get a moter, wire, plug, and switch so you can hook it up, plug it in, and start or stop the motor.

Visit your hardware store and get four bearings that can be surface mounted and two matching shafts at least 4 inches longer than your barrel; 3/4 or 5/8 inch diameter shaft works. Get a couple of V-pulleys for the shafts - 2 1/2 inch for one and 8 for the other is a good guess with a 1750 RPM motor, 5/8 shaft, and 10 inch barrel. Pick up a belt long enough to connect half the barrel diameter plus half the motor diameter. Pick up nails, screws, etc to put it together.

Stop at your local lumber yard and get a couple 2x4s twice the diameter of your barrel. Pick up a couple sheets of plywood; one twice the diameter of your barrel x the length of your barrel cylinder plus about 4 inches, and one the diameter of your barrel x the length of your barrel cylinder plus about 4 inches.

Lay down the big sheet of plywood, set the 2x4s along the sides, and lay the small sheet of plywood across one end of the top. The barrel should fit on the other half and just slide between the 2x4s. Fasten it together.

Mount the motor on the top of the small plywood sheet with the shaft hanging off one side. Mount the two shafts about 3/4 barrel diameter apart on the other half of the top with bearings on the 2x4s; the drive shaft should extend past the edge the same length as the motor shaft and on the same side (and be the shaft closer to the motor). Big pulley on the drive shaft, small one on the motor, and the belt connecting them should be fairly tight. Mounting the motor on a hinged board can help with tension issues on the belt.

The rotating speed is dependent on the barrel diameter. A four inch diameter barrel should rotate 50-60 rpm, and an eight inch barrel at about half that rate. Remember the barrel forms another 'pulley' speed change with the 1/2 inch drive shaft it rests on. The drive shaft speed depends on the ratio of the pulleys on the motor and the drive shaft. A typical example would be 1750 rpm motor and 1 inch driver and 6 inch driven then the final drive would be 1/6 of the 1750 RPM or 291 2/3 RPM. With a 4 inch barrel you get 36 and almost 1/2, which is too slow; changing to a 4 inch driven pulley gives you 54 and just over 2/3 RPM, which is about right for a 4 inch barrel.

If you need help with pulley sizes visit http://www.wfmeyers.com/customer/calculatorPulley.html.

The top of the illustration below shows a (very) rough drawing of a finished tumbler (minus the barrel, which will rest on the two rollers at the left), and the bottom shows a rough sketch of the frame before mounting rollers and motor. Note that the frame needs to be rigid, the rollers need to be parallel, and should be at right angles to the sides of the frame.

Connect both shafts together on the opposite sides with the same size pulleys and a belt if you want them both to drive (it helps with larger barrels).

Hook up the motor, put on the barrel, and start tumbling.

And if you want to see a polished example, take a look at the impressive machine Alan Lewis made from these plans.

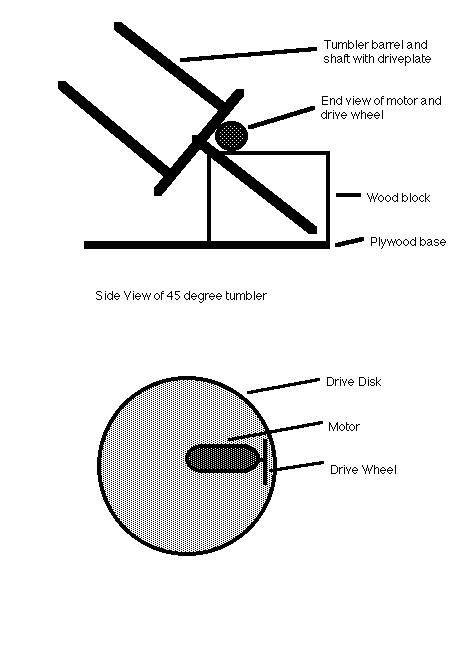

Above I covered the traditional tumbler that has the barrel rolling on its side laying on shafts that support and drive it. This posting will cover the more difficult 45 degree tumbler. With this tumbler you can use an open top barrel making it great for schoolrooms (add some plexiglass guards over the moving parts for safety in a classroom).

In this type of tumbler the shaft is attached to the bottom center of the barrel, and the barrel and shaft as a unit are tipped to a 45 degree angle, shaft down - open top of barrel up. The shaft is supported by a base block. The motor shaft has a small wheel on its end that rides on the bottom outside edge of the barrel to drive it. It can be made to spin faster by moving the drive wheel closer to the center of the barrel bottom or enlarging the size of the driving wheel.

The barrel and shaft are really a single unit. For a small tumbler you could use a large plumber's helper (plunger) - the type that is shaped like a wine glass instead of a cereal bowl. For a big tumbler a steel shaft with a floor flange on one end, a circular plate attached to the floor flange, and the barrel base attached to the top of the plate. Fastening a holder (large bucket?) container that your bucket just fits into on the top of the plate is an easy solution and makes the barrel removable for cleaning. The plate will be used as the drive surface. For the plunger you need a washer shaped plate and a floor flange that you can slide down the handle and fasten on. It is important that the drive plate be at right angles to the drive shaft and be rigidly attached (and thick enough not to flex) - plywood works.

Get a motor, wire, plug, and switch so you can hook it up, plug it in, and start or stop the motor. You need to be able to fasten a small wheel to the end of the shaft. Alternately, the wheel can be on one end of another shaft that is pulley/belt driven by the motor - and this actually helps since most motors you will find are probably a little fast unless your drive plate is larger than the barrel by a few inches. The drive wheel and the plate make a pulley system, so you can figure a reasonable speed ahead of time and make your drive plate large enough, or reduce the speed with pullies by using drive from the second shaft.

The end of the barrel shaft is going to support weight and needs a thrust bearing. The top end of the shaft can use a regular bearing. If you are making the plunger type you might be able to do without a bearing if you drop a large marble or ball bearing in the support hole before putting in the shaft (and lubricate the shaft with bar soap). Make sure the barrel shaft is long enough to support the barrel weight; its a lever and probably should be near the height of the barrel.

We're going to need a large cube of wood. Your shaft will need to be about the length of the diagonal of a face. Stacked 4x4s with side bracing can be used in place of a block of wood. For something large, you might want to use a concrete base with a 4x4 imbedded where the shaft will go. This base block will be fastened to one half of a board twice as long as it is wide (and at least as wide as the support block). The barrel will hang over the part of the base not covered by the block, which is there to keep the whole thing from tipping over.

With the base assembled, the shaft/barrel assembled, and a motor we're ready to put it together. One side of the cube rises up from the base at its center. At the top center of this edge we're going to drill a hole 45 degrees downwards to the center of the bottom edge that is at the outside of the base. Don't drill all the way thru if making a plunger tumbler and make sure the shaft just fits the hole; otherwise drill a hole large enough for the shaft, mount the bearings (thrust bearing at the bottom, regular bearing at the top), and line them up with the shaft. The drive plate should be a little ways above the block when the shaft is inserted. If you are not using bearings, make sure the hole is smooth and closely fits the shaft - drill a smaller pilot hole first.

Mount the motor so that the wheel on the end of the drive shaft pushes up against the bottom of the drive plate at its edge. The axis of the drive shaft on the motor should point at the center of the barrel shaft. As the drive wheel turns, friction against the base plate makes it turn.

Hook up the motor, put on the barrel, and start tumbling. Don't fill your barrel too full or it will splash out the top. If the barrel has a small neck, like a wide mouth mason jar, that is a good thing.

And if you want to see one of these built by Bruce Mitchell on an industrial scale, check out the monster tumbler at Machine Intelligence.

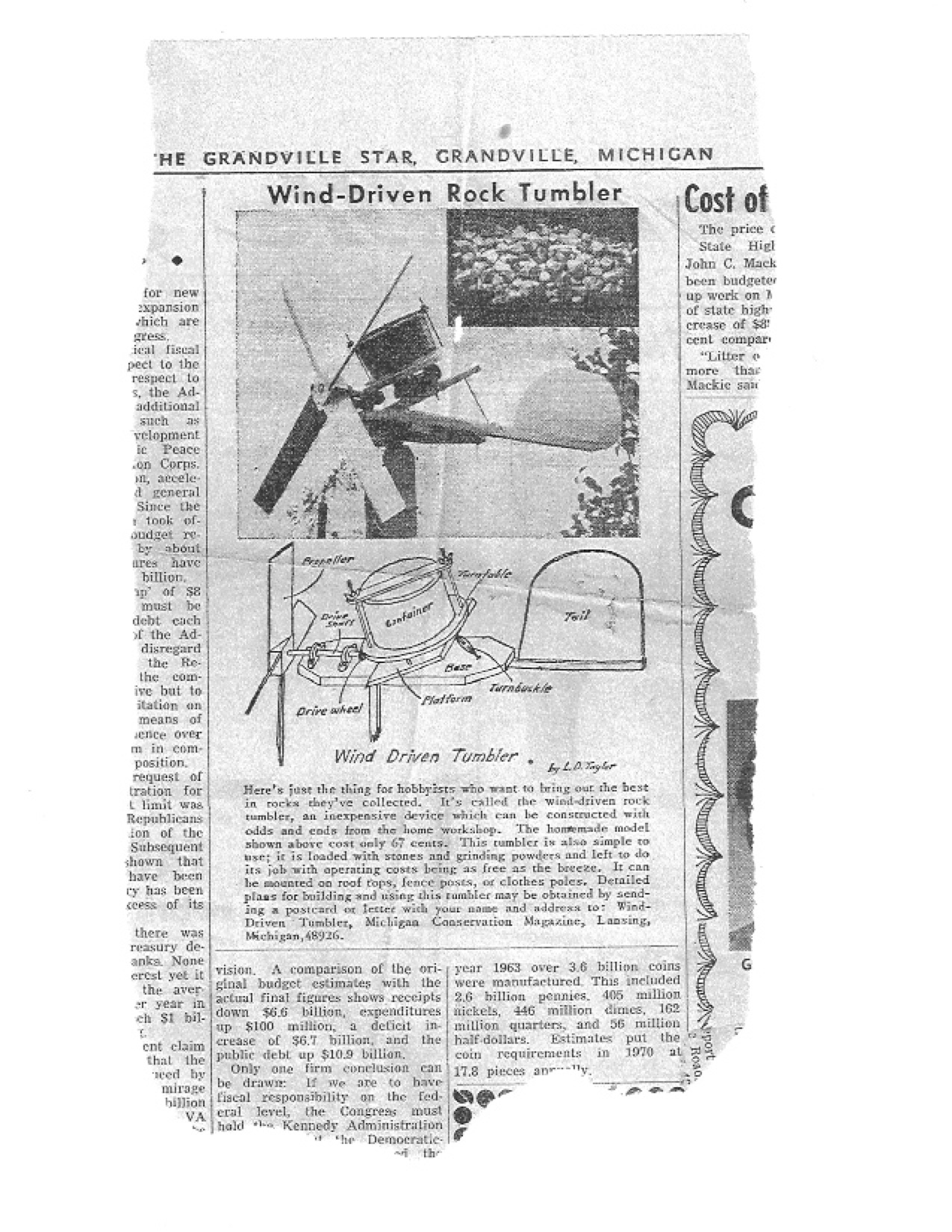

Michigan Conservation Magazine adapted one of these 45 degree tumblers to wind power and the plans were advertised in The Grandville Star newspaper dated August 15, 1963.

Everyone who tumbles seems to have a different preferred set of steps/instructions, so there is flexibility in the process. Keep some notes on what you do so you can see what works and what doesn't over several batches to improve your success rate.

In tumbling you are going to roll stones in a barrel with grit and water thru several stages, from coarse to fine grits, so the stones are very smooth. You will then use a polish sequence to finish up and produce the desired shine on the stones. It is best if each barrel is composed of stones with close hardness.

To start you are going to need to fill the barrel with stones until it is 2/3 to 3/4 full. Add water to roughly the level of the stones. Add the coarse grit (small grit #'s are coarse, larger grit # grades are fineer) -- a heaping tablespoon full per 1/2 lb of stones. Seal up the barrel and let it run for a week to 10 days (longer if the stones have a lot of sharp edges, shorter if they are already rounded).

Check the barrel. You should now have smooth, rounded stones with a frosted surface. If not, run the coarse a bit longer. Coarse grit is the most important stage.

Clean everything up, rinse out all the grit (many folks say don't run it down the drain because it tends to form hard blocks - more on this later). Run the stones with water and some soap for an hour or two, and clean it all up again. A single coarser grit particle transferred to a finer stage can ruin the polish on the whole batch, so do a good job of cleaning between stages.

Repeat with medium, and then fine grits, about a week each, cleaning again between steps. Grit does break down during tumbling to finer grades. Some folks recommend using coarse for a month or more and then moving to polish. Others prefer to run thru grades, which is more 'traditional'.

If the barrel ever gets under 1/2 full (the stones will shrink during each stage, most during the first/coarse stage) you need to add filler; tumbling generally works best when the barrel is 2/3 to 3/4 full. Plastic pellets, wood chips, sawdust, dryer lint, leather scraps, crumbled styrofoam, and rejected stones from previous batches all have been known to work. Replace the filler with each grit change.

So far we've been scratching the stone surfaces with finer and finer particles of grit. You may want to follow the grits with a pre-polish stage (if you have it) for another week, before moving to polish (do a good job cleaning). Polishing works with a butter smoothing like process that fills the scratches with the higher surface. If you don't do a good job in grinding you can't get a good polish.

Run the polish stage after a very good cleaning, again for about a week, with filler if necessary. You should now have stones that have the same glossy surface wet or dry.

Clean everything up, add filler, and run with soap (Tide) and water for 3-5 hours. Rinse it all out, let it dry (some folks hand wipe everything with a towel), and you are done.

If you want to look at an old tire homemade rock tumbler that can do larger stones, and get info on how to construct one, go to

www.acc.umu.se/~widmark/lwtrumlc.htmland

www.acc.umu.se/~widmark/lwtrumla.htmlor if you want a really big tumbler, here is one made from a truck tire

www.acc.umu.se/~widmark/lwtrumld.html

and another tumbler option from Agate House (click Lapidary, Homemade)

For someone getting started I would recommend getting one of the smaller one or two barrel (about a quart barrel) commercial tumblers such as a Lortone. Find a rock/lapidary store that carries tumblers (or search online), and grit packages (I usually use half the 'recommended' amount, and recycle it too). I still use my two barrel as much as my other four tumblers put together. One big stone can be tumbled by itself, or with some 'pea' gravel (or garnets), in a small barrel.

Replacement barrels for the commercial units (especially the larger sized ones) are great for home made tumblers. You can also find suitable barrels as replacements for some industrial equipment. The barrel is the most difficult part to make, and if you're making your own you almost have to have the barrel first so it comes out the right size.

Rubber lined pipe with a flange at both ends, to accept bolt-on rubber coated plates, works for bigger barrels. Making your own involves metalwork, welding, and fitting it with a rubber lining (or making seperate barrels for each grit). I've seen modified 55 gallon drums, cement mixers, and tractor tires used as barrels. Get some experience with a commercial tumbler before trying to make your own barrel.

Cleaning between grits is important. Use a toothbrush and scrub the corners of the barrel. Run the load with water and laundry soap for a half hour and rinse (repeat until you get clean water). Poor cleaning is usually the cause of poor polish; the second most likely cause is not using the coarse grit long enough to get a smooth and even surface.

Check out the archives of the Lapidary Journal online (join the email list too -- see my Links page) for advice on tumbling. Find the nearest rock club; local help can't be beat. Follow the directions that come with either a tumbler or a grit package (at least the first time). Try to keep the stones in a load close to the same hardness. Learn to do pebbles before you try boulders (they're more difficult and much noisier).

Foam/Froth is not always bad.

Too small a load prevents the rocks from climbing the side of the barrel far enough so that they tumble. The extra resistance a little foam (or froth) soon provides in this situation can cause tumbling action to slow down or stop.

Too much water can thin down the froth and prevent it carrying the grit throughout the load. Instead the grit slids along the (uphill) bottom of the barrel as it rotates, and stones that tumble land on little/no grit.

A good froth (or foam) will carry the grit throughout the barrel so that any stone collision is likely to have a grit grain rubbed across the surface. Tumbling action actually improves with a good froth for most minerals/rocks.

A good froth will also take the sharp edge off sounds produced as the stones tumble, but you will still hear them tumbling. If they stop making a tumbling sound once the froth gets going you probably have too small a load and need to add some filler. If you don't want to add filler the traditional approach has been to clean the water by rinsing out the mud with a slow stream of water that won't remove the grit (hard to do on fine grades).

BTW, if you like to start with coarse and tumble until it is used up, prepolish, and polish, the froth provides the filler automagically to compensate for the the diminishing payload size. But if you don't have enough water it hardens into cement about half way thru and tumbling stops (and you must rinse).

The problem with froth and amber (that is often mentioned as an issue) is that amber has a specific gravity of only 1.05 - 1.10 (in better specimens). The froth can easily become denser than that (remember, water is 1, and most minerals are at least an integer multiple higher) and literally float the stones. Froth elutriation is an important method of (dense) ore concentration, but would be undesirable with the almost floatable amber. Adding too much water (or too much grit) does help in tumbling amber.

I stumbled across Alan Silverstein's Collected Information on Rock Tumbling website. He has interesting details and tips; I was pleased to have found it, and you will be too.

And have fun!

Before the diamond blade was invented people used brass (or copper or iron) disks and carborundum grits to make a rock saw. The blade was partially immersed in water and grit, much like today's diamond blades are immersed in coolant. The spinning blade carried water and grit up to the rock, and pressure of the blade against the rock charged the edge with grit so it would cut. I recently used a similar technique with a soupcan and grit to cut circles of glass (also works on slabs) with some details available in the Drilling Holes article elsewhere on this page. But this is about rock saws, so here is the basic idea

|-| <=splash guard

|

|

|----------| ____|____ <= table surface

| Motor |=========|

|----------| |

| | |

| | | <=bin for liquid with blade immersed

|_____|

The simple technique for making a saw is to connect a motor to a blade, either directly or thru a pulley.

|-| <=splash guard | |-| | |-| ____|____ <= table surface |-|=========| |-| | |-| | | | | | | | <=bin for liquid with blade immersed | |_____| | |-| |-----------| |-|====| Motor | |-| |-----------| ^ Pulley and belt

Diamond saw blades are what set the speed for a traditional rock saw. Each blade manufacturer sets a recommended and maximum speed for the type and size of the blade. For example, a 6 inch blade has a typical recommended RPM of around 6,000 (max 10,000), an 8 inch is 4,500 (7,500), and a 12 inch is about 3,000 (5,000). The belt/pulley connection between the motor and the blade is adjusted to give the proper speed per the blade manufacturers recommendations.

Typically a 1/4 horse 1,760 rpm motor is adequate. Pressure of the rock being cut on the blade is minimal to prevent overheating of the blade and its self destruction. You don't need a lot of power and can't force faster cutting; you have to let the diamond blade do the cutting at its own rate.

Because using a pulley and belt drive requires a second shaft, I opted for direct drive on my original home made rock saw. I also made a dry saw using a carbide cut-off wheel instead of a diamond blade (which are now available in wet and dry versions). I found a motor that let me fasten the blade directly to the shaft, mounted it on a platform, and built a table over it (with a slit for the blade) with wood. Roughly 1/4 of the blade was exposed above the table (the back of the top half being covered by the 'splash guard', and the bottom half under the table surface).

You can use the smooth back of a regular wood saw and carborundum grit to cut rock if you have a lot of patience. It takes work to cut quickly as you must bear down to get the grit to cut fast. But it works!

If you prefer a wire saw, you have a couple choices. It can either be continuous, like a bandsaw (which you might be able to adapt by putting the blade on backwards and use the smooth edge with grit), or reciprocating (back and forth). Why not use diamond wire like the commercial quarries do to cut big blocks? At least one source you can buy it from can be found on my Links Page, and others are available by using your favorite search engine. Then you don't have to charge the wire with grit.

To make a reciprocating wire saw, you connect a wire to the side of a wheel, run it over a pulley, and connect the other end to a spring (bungee cord, small tree sapling). As the wheel turns the wire is pulled back and forth. Hopefully this rough drawing will come out

_________________

/ \ ()\

( o ) \

\___/ \()_______________________()()()()()()

wheel ^ pulley ^ cut here spring ^

Replace the cutting portion of the wire with a length of iron or brass strip, and you have a more normal reciprocating saw.

Of course, the quick solution is to buy one of the dry diamond blades contractors use and toss it into your table saw. Wear eye and dust protection!

But READ your table saw's Owner's Manual first!The usual problem with trying to convert wood saws is that the bearings are not sealed. They can handle the relatively soft sawdust that will get into the bearings, but abrasives, rock dust, or metal shavings would destroy the bearings.

You will also have to check the rpm rating on whatever diamond blade you decide to use. You may also need to cut the speed of the saw. Running diamond blades too fast just burns them up.

Good luck in your project. I hope some of this helps. And please remember that all machinery is dangerous (especially if home made) and take proper precautions (especially eye protection).

Horizontal laps are more difficult to make with their vertical spindle. The spindle needs to be more rigid than the traditional grinding wheel, and must also deal with downward pressure (a thrust bearing). The alternative is the type of machine used by amateur astronomers to make optical flats; some of these may be adaptable to lapidary work, but they do not seem to be the answer. The laps or grinding wheels need to be 'true' round with well centered mounting to avoid wobble when spinning.

Two solutions for mounting/changing laps are common. The first is reverse threading the top of the spindle (at least reverse relative to the rotation), have a hole in the center of the lap, and go on with a single nut over a washer. You can use regular grinding wheels and (flat/round) sanding disks (foam on plywood - peel-em-off cement to hold the disks). You can also use iron or brass laps and grit/diamond dust in the traditional manner. I added sphere cutters to mine. You lose the middle couple inches of the lap due to the spindle sticking up.

The other style is like the end sander on most combo grinder units and has a back much like a pipe flange and holds onto the shaft with setscrews (like a doorknob). You get the whole lap surface. Laps are more expensive.

BTW, you usually need a different lap for each grade of grit or polish you are working with (except peel-em-off sanding disks).

Drip pan is more complex. Think of the lap sitting on the middle of an angel food cake pan. Shaft extends downward and is pulley/belt connected to the motor. Use a washing machine motor that expects to be mounted vertically. I've been told that a washing machine can be converted into a horizontal lap if you remove everything but the drive unit and controls.

| Drip pan | ----------+--+---------- Lap | |^| |^ Shaft | |=| |= Bearing | | | | |____________|=\ /= Cone (thrust) bearing | |==||== | leg || Shaft | || | ====||==== Pulley ====||==== | ====||==== ====||==== | || Table ==================================== --++--- |Motor|And if you go to www.hisglassworks.com and follow the links for flat machine grinders you will find a download link with plans for building your own flat lap.

Jon Rolfe also has plans for making your own Faceting Machine on his website at www.gearloose.com/newgem.html

Plans for faceting and cabbing machines can be found at The Gem Connection. More homemade lapidary equipment plans can be found at Agatehouse and Autodidactics.

When I am cracking geodes, or splitting/trimming specimens, I use a 'nutcracker' made from a big vise, two triangle files, and some tape. Open up the vise and tape the two triangle files to the faces, a flat side of a file to the vise face. It helps if the files point in opposie directions so their tapers offset each other. Center them along the vise faces so their pointed edges line up and meet.

You are going to use these two tool steel edges to split a rock on the line/plane between them. A vise can apply a lot of pressure -- a rock can be very tough. Trying to split a rock thicker (in any dimension between the edges) than half the width of the vise face, could break a vise. (Been there, done that... more than once!). That 'half' figure is by trial and error - I have not broken one at this limit yet, but your mileage may vary.

Wear eye protection. Splitting rock often propels shards. Be prepared because the two side of the split rock are liable to take off up and down. (Wrap the vise and rock in a towel). You might need, or want, to add a two or three foot length of pipe over the vise handle, to get easy leverage. Be careful! That leverage can be deceiving. It makes it much easier to break your vise! Pounding on the handle with a hammer, to tighten the vise, can also help break a stubborn rock. (Again, note the previous caution).

My experience is that about 5% of rocks fail to break on the desired line, and about 10% crumble aling the break line about half way and then break. Another 5% are just too tough to break, so you need to know when to give up, or you will break a vise. The rest are well-behaved, and break as expected.

Don't say I didn't warn you -- you can break a vise trying this. But it works most of the time, and you might want to consider trying it.

Most (city) water systems supply the liquid at 60 psi. You can make a poor man's water gun with a hose and a brass end cap.

Using the smallest drill you can find, run a hole thru the center of the brass end cap. From the inside of the cap, and using a large drill, bevel the inside of the hole - but don't go more than 1/2 way thru the brass. Put the cap on the hose, hook the hose up, and turn it on. You should get a very fine stream of water coming out with at least 60 psi of pressure (I have been told hydraulic effects can increase this up to 200+ psi). If all you get is a fog, your hole is too small, or is not smooth (or is plugged with sediment from the pipeline).

Its nothing like an expensive unit (which I have used but don't own), but it does do a reasonable job, and it probably won't damage the delicate crystals a manufactured unit would. And using it with a small (soft) toothbrush does wonders.

There are a lot of projects that may require making custom metal parts. Molding and casting is a way to solve this problem and you can do it at home. Good plans and information on this can be found at MyHeap.com.

Crystal growth can be a complex subject, but the steps for growing your own crystals are pretty easy.

Pour some hot water (or other solvent of choice) into a clean container. Warm solvents generally can dissolve more substance than cold, and this is important because we want a saturated solution. Now start adding the substance to be crystalized - lets use table salt for this example. Dump some salt in your hot water, and stir to dissolve it. Dump some more salt and stir. Keep doing this until you can't get any more into the solution and you have some at the bottom of the container that is not dissolved.

Pour most of the hot liquid into another clean contaner. We don't want to pour it all because we're trying to avoid getting any of the undissolved crystals at the bottom. Set the container on a shelf where it will be undisturbed for a few hours and let it cool. Wash out your first container, and make sure it is really clean.

As the liquid cools it will start forming crystals from the excess salt the hot water was able to dissolve. After a few hours (to overnight) you will have a room temperature saturated solution of salt. This liquid, with no crystals, needs to be transferred to a clean container.

Now you have a clean container with a saturated salt solution in it, and a dirty container with a bunch of small crystals in it. Pick out the most perfect crystal you can find and drop it in the solution. This is your seed crystal.

Put the solution with the seed crystal in it back on the shelf. As the water slowly evaporates it will add salt to the seed crystal. The seed crystal won't dissolve because the solution is saturated. In a few days you will end up with a much larger perfect crystal.

In nature groundwater provides the saturated solution. Other substances in the water complicate the process, as do varying conditions. But the process is much like growing your own crystals in the kitchen.

Jack Schmidling used to make (and sell -- I have no connection with Jack other than finding his website from a list posting; this is not an endorsement of his wares) his own Faceting Machines. No complete plans, but his descriptions and pictures would get you a long way towards building your own. My thanks to Jack for keeping this information available to the collecting world. I was most impressed and am glad to be able to share the discovery.

Anyone who can make telescopes can certainly meet the tolerances needed for faceting. Amateur astronomers like Jack meet the same polishing issues (in glass) we Lapidary do, but at much higher tolerances; the same for their equipment. If you do lapidary, you can learn a lot by finding out how astronomers grind mirrors, make lenses, flats, and other optical elements out of glass.

And if you want to make your own castings for machinery you probably need to build a cupola furnace.

I said many times, "Now if I could only find plans for making a vibratory tumbler...", ..., and then "Steve" came to my rescue (Thanks!, again, "Steve"). He pointed me to Don Ashe's plans for making a vibratory tumbler (you are looking for a "Homebuilt Brass Tumbler", about a third of the way down the page -- but I was impressed enough with www.buildgear.cjb.net as a 'make it myself guy' that I wanted to give full credit to a most interesting resource).

As you finish each grade of tumbling, dump the grit and mud and water into a bucket and let it dry. The mixed minerals and grit have different dimensions and densities. Elutiriation lets you regrade this mixture and recover the tumbling grits, by grade, for reuse. You may never need to buy anything other than coarse grit again (grit is broken down to finer grades during tumbling).

Glad you asked what elutriation is...

Elutriation is the seperation of mixed substances by size (if uniform density), or by density (if uniform size) using an upward flow of water (or some other fluid, including air, but water is assummed).

And now I'll bet you want to know how it can be done. And yes, you CAN try this one at home.

The easy part is finding a two liter plastic pop bottle. We're going to use it up-side-down, so cut off the bottom, and try to leave a level edge. Set the bottle on a flat surface, and place a book next to it so you can lay a marker on the book, turn the bottle, and draw a level line around it near the base. Cut on the line with a sharp blade (be careful you don't cut yourself), and trim as needed to make it reasonably level. Throw away the cap.

We need to find some rubber or plastic tubing (a section of garden hose?) that can be worked over the bottle top (where the cap was) to provide a flow of water. We will then mount the bottle with the cut off bottom up, and the hose connected top down, over a large pail or bucket (the hose should make a U turn and come back up over the bucket so drips don't end up on the floor).

We will be connecting the hose to a water supply, be putting the stuff to be sorted by size or density into the up-side-down bottle, and letting a slow water flow carry the smaller/lighter stuff over the cut off bottom of the bottle so it ends up in the bucket under it.

If we start with a real slow water flow first, we can take off only the smallest/lightest stuff. Put down a new bucket, increase the water flow slightly and you get the next grade of grit. Repeat until all you have left is the coarsest stuff in the up-side-down bottle.

If we start with a fast water flow first, we leave only the largest/heaviest stuff in the up-side down bottle; save it. Let the bucket settle, drain/siphon/evaporate off most of the water and transfer the 'mud' in the bucket back to the (now empty) bottle. Repeat with a slightly slower water flow and seperate out the next grade. Eventually you end up with the finest stuff in the bucket. Since this is probably mud, you can dispose of it (but not on your garden, it might contain toxic minerals).

When working with recycled grits, the finest stuff is probably mud from what was ground with the grit and needs to be disposed of. The stuff in the bottle on the last cycle of regrading new grit, is the stuff you want to use last to get that super sanding that looks like polish. Its the finest grit that has been broken down far beyond the grades you can usually buy commercially.

The key is the water flow. If you want reproducable sizes/densities you need reproducable water flows....

City water pressure is usually 60 pounds/sq. foot, and much too high pressure to use for this. You might have a faucet you can graduate for the various grits, but it is unlikely. You probably need to use one of the alternatives below:

A. Between the faucet (which will be wide open) and the bottle the hose must be reduced in size. Use two sections of hose, and connect them placing a washer with a small hole in it in the line like a shower flow reducer. Vary the size of the hole to get different flows.B. Between the faucet (which will be wide open) and the bottle the hose must be reduced in size. Use two sections of hose, and connect them placing a glass tube that has been 'drawn' in a flame to reduce its diameter in the line like a shower flow reducer. Vary the size of the hole to get different flows.

C. Near the bottom of a bucket drill a hole and connect the hose from the up-side-down bottle to it. Drill several more holes up the side of the bucket Plug all but one with corks. Pour water into the bucket (with a hose) so that some always runs out of the open hole. Increasing the depth of the water in the bucket will increase the flow out of the bottom hole connected to the hose. Don't fill it so fast that the water level goes over the top of the overflow drain hole in use.

D. This is a variant of C where the height of the bucket above the up-side-down bottle is changed (lower is slower) instead of changing the depth of water in the bucket.

Its a little bit of work to get it running and calibrated the first time, but once done it can be used over and over again to give reproducable results. And you may never need to buy anything other than coarse grit again, because tumbling with coarse (or any other grade) produces the finer grades as the grit is broken down.

And if you want to work on different densities, try using it on sand or gravel that is known to contain gold. Its very dense and remains in the bottle. This scales up and is used in many commercial mining operations. Most ore is denser than the matrix rock, so crushing the rock and elutriating it will seperate the rock from the ore.

Enjoy!

The 'Wichita case' is designed to utilize standard size window glass, can be used in horizontal poistion at shows, can be disassembled for auto transportation or storage, - and here is the prize-winning hidden feature - it can be easily transformed with the use of pins and three shelves into an upright case for home use between shows.

Here is how the case is made and it goes without saying one had better be handy with tools.

A 1 x 12 board 14 ft. long will make three cases with no waste if properly cut. Saw this into three boards 23 3/4" long for the sides of the case and into three boards 30 3/4" long for the fronts and backs. The boards must be cut on a saw that cuts absolutely square. Now split the 23 3/4" board diagonally from one end to the other, in such a manner that the larger or back ond of each board will be 7 3/4" wide on the inside face of the back panel and 3 3/4 on the inside face of the front panel. All sides should now be grooved for the glass and masonite. 1/8" non-tempered masonitge is used. The glass is 24 x 30" double strength window glass; single strength is too flimsy fr the lie down case.

The groove should be 1/4: deep for the masonite and 7/16: deep for the glass. The masonite groove should clear the bottom of each panel 1/4". The glass groove should open at the top to allow the glass to drop in. Groove in ends of front and back boards 3/8" for the side boards to join the front and back.

Put front and two sides together, slide in masonite, then put on back. The glass drops into the 7/16" groove on top. Ten screws, size 8x1 hold the case together, three on each side of the back and two on each side of the front. Use no glue as it is designed for quick disassembly for transportation or storage. It can be painted, stained, or varnished. Brass corner strips or pieces of wood may be added to the top edge of the back and front to hold the glass in place if desired.

This case may also be used upright for display in the home. The original back then becomes the bottom and shelves are fitted in. These shelves are 5 3/4", 4 3/4", and 3 3/4" deep by 20" long and are set on 1/8" pins set in bored holes. thus the shelves can be removed quickly and the pins pulled out so the case can be used for flat display.

Variations of above may be used to please.

From: "Quarry Quips", Wichita Gem & Mineral Society, Inc.In fairness I must admit I have never actually made one of these, but the plans seem reasonable; I have only used them, borrowed or purchased, and always thought them to be quite handy. I've seen five variations on this writeup, but all agreed on 'Wichita', and the dimensions -- but this was the only one in the 'public domain'. I hope you find it useful.

From: "the Glacial Drifter", The Grand Rapids Mineral Society (vol 2 no 9, Sep 1960)

All stones used to be polished by hand - machines are a relatively new invention in the history of polishing rocks. Lets take a look at really 'hand made' ways of polishing rocks. I first learned this process with Petoskey Stones.

I assume you've guessed that to get a good polish the surface of the rock must first be ground very smooth by something harder than the rock being polished. River and beach stones might be an exception in some cases. Carborundum sandpaper (or plain sandpaper for most rocks softer than quartz) works great. Start with a grit under 200 and smooth the rock off. Change to (around) 400 grit and do it again. Change to 600 and/or 1000 and do it again. This is going to take some time, but the effort is needed if you are going to get a good polish. The harder the rock the longer it will take. Each finer grit must erase the coarser scratches from the previous grit before you are done with it.

Glueing your (small) rock (elmers glue works) to the flat side at the end of a length of wooden yardstick (6-8 inches long), so you have a handle, sometimes makes it easier to hand grind and polish a stone because it is easier to hold. A piece of newspaper between the stone and the wood can make it easier to remove (soak in water overnight) when done.

Traditional rock polishes are substances like Cerium Oxide, Rouge (not the makeup kind), Tin Oxide, and Barnesite. Felt or leather (chamois) are commonly used for polishing. You can probably find most of these at your local hardware store. A little bit of polish goes a long way.

But you can use a piece of chamois (leather wipe used for polishing cars) and plain old toothpaste (not sure about gels, but they would probably work too) for the polish. A piece of felt, a cloth diaper, a scrap of bluejeans, or even a handkercheif works, if you can't find the chamois. Printers Ink, like they use to print newspapers, also works as a polish but is very messy (and you can use it with newsprint too - after you read the news, polish your rock with the front page). Most liquid shoe polishes also work if you rub hard enough to wipe the stone clean on every pass (best with diapers). The stone will start to warm up when you are pressing hard enough in the polishing.

Good polishing takes a fair amount of pressure when done by hand, or a very long time if little pressure is used, the same as grinding. If you spend more than 100 hours on a rock surface smaller than six inches diameter you are doing something wrong (most will take around 40 hours). Small rocks take almost as much time as big rocks since you have to be more careful. A petoskey stone or a piece of hard marble makes a great first stone; granite also works, but is a bit harder and will take a little longer (but takes a better polish). Agates and Quartz are even harder and take longer (and give better polish yet); in general, the harder the stone the better polish that can be produced. You might also consider a piece of dolomite, or hard limestone.

The above process was for smaller stones (but would work on larger ones too). If you have large flat surfaces, like a slab (of, say, petrified wood), a cut thunderegg or agate, or a cut geode, you would like to polish there is an alternative. Note your surface needs to be reasonably flat to begin with. Start by giving it a once over with an emery stone to take any sharp points off the surface.

Get a sheet of glass (1/4 inch plate, or thicker, preferred) and lay it on a sheet of newspaper on a flat surface. Sprinkle loose carborundum (tumbling grit) in the middle of the glass surface, lightly/randomly covering an area a little larger than the rock surface to be polished. Start with 200 grit and work thru the various grades as usual. Grinding is done with the flat surface against the glass, which is a tool. When the glass and rock surface have an even 'frosting' you can move to the next finer grade of grit. Use a short 'W' shaped stroke with short 'O' strokes mixed in randomly. If your grit gets dry, sprinkle a little more water on it. After a while of grinding the grit will be broken down and stop cutting. Sprinkle on a little more grit (a salt shaker works) and water (a spray bottle works) and continue until the surface is even and you are ready to move to the next grit. Clean rock and glass between grits and use a new sheet of newspaper. One grain of 200 grit when you are on 600 can send you back to 200 or 400 if you don't want to live with a large scratch.

Polishing can be done with the usual compounds on the smooth surface on the other side of the glass you've been using, but is not easy. A better solution is to find honeycomb foundation stock at a beekeepers supply or feed store. The thin beeswax sheet with the start of the hexagonal wax cones is a great polishing surface. Stick it to your glass by warming with warm/hot water. Slather polish (teaspoon to a cup of water) on the surface with a paintbrush, and start polishing (harder with geodes than slabs). When it starts to dry you should be able to wet it a couple more times before needing to re-slather with polish solution. Coal tar pitch or rosin, as used by astronomers to polish telescope mirrors, works even better, but is less available than honeycomb foundation.

I would also suggest you look for a rock club (or rock store) where you can find other Rockhounds. Personal help from fellow hobby enthusiasts can't be beat. But if you are doing large flat polishing by hand, you might better find a local astronomy club and talk to their telescope and 'flat' makers about technique.

In its March of 1932 edition (pages 144-146), Scientific American published an article titled "Gem-Stone Cutting for the Amateur" by J. H. Howard (of Rocks and Minerals Magazine) that appears to have been key to the creation of the lapidary hobby in America. This widely read article described how to make lapidary equipment and use it to cut and polish 'gemstones'. The large response to the sharing of knowledge was our shared hobby of lapidary.

I would like to be able to share my copy of this article, but the copyright does not expire to the public domain until 2027 and Scientific American refused my re-publication request; you will need to find your own copy (hint, talk to your favorite librarian about finding a copy via inter-library loan). The article is worth the effort it takes to find a copy for its outstanding clartity in presenting the fundamentals of the lapidary craft.

Thank you Mr Howard.

You have found this (old) lapidary machine and need a part or manual, or just some more information, to get it going again. You have a name and a model number, and a good description. Whatever happened to...

- Abrasive Technology

made the Crystalite faceting machine.

- The Addexton Company

at 530-666-4817, in Woodland, California, makes automated cabbing systems, flat laps, grinding systems, and rock lathes.

- Addington Co.

at PO Box 73585, Davis, CA 95617 (530-753-3753) makes a Jamb Peg Faceting Unit.

- Altamont Manufacturing Inc., in St. Joseph, IL, manufactured a Sensor II automatic cabbing machine.

- Amber-Werx, at 75 Forest Lane, Wolcott, CT 06716 (203-879-1912) manufactures the EZ-Kutter line of lapidary equipment and accessories.

- Anand Engineering Works

at 72-A, Diamond Bazaar, Trichy - 620008, India (91-431-704101) makes Faceting machines and accessories.

- B & I Mfg. Co., in Burlington, Wisconson, made the Gem Maker in the 1960s and 70s .

- Barranca Diamond Products Inc., in Wolcott, CT, manufactures the EZ-Kutter line of lapidary polishing equipment.

- Beacon Engineering Co. was acquired by Diamond Pacific Tool Corporation some years ago.

They were in Rothsay and Moorhead, Minnesota, and made Beacon Star grinding units and saws. They also made a Winkler Star tumbler.

- Cab-Master was acquired by Diamond Pacific Tool Corporation some years ago.

Cab-Master made the Cab-Master Tool, a slab grabber.

- Comco, Inc. is in Burbank, CA, and makes micro abrasive blasters for cleaning or drilling of fossils or stones.

- Contempo Lapidary was acquired by Diamond Pacific Tool Corporation (800-253-2954) in 1997.

Contempo Lapidary in Sylmar made combination lapidary units and saws.

- Covington Engineering has been making lapidary and glass forming equipment since 1848.

- Crown Lapidary Equipment Company

in San Marcos, CA, made a multi unit with four diamond wheels and two buffing stations, and the Crown Bead Mill.

- Crystalite

Crystalite made Demon machines (the Demon Master had a 6" diamond blade and wheel) before going out of business.

- Crystal Mark

is a manufacturer of micro sandblasting systems in Glendale, CA.

- Diamond Pacific Tool Corporation

in Barstow, CA, makes a complete line of diamond lapidary equipment.

- Dunbar

in Vancover, BC, Canada, made a trim saw and a arbor.

- Eastwind Lapidary, Inc.

in Windsor, VT, distributes a complete line of diamond lapidary equipment and manufactures flexible diamond abrasive belts and discs.

- Edus

in Idar Oberstein, Germany makes automated cabbing systems.

- Exata

in Covina, CA made faceting machines.

- Fac-Ette Manufacturing, Inc.

at P. O. Box 550, Wrightsville Beach, NC 28480 (910-256-9248) makes GemMaster faceting machines and accessories.

- Frantom was acquired by Contempo Lapidary around 1981.

Frantom made saws and grinder/sander units. Tom and Fran ran the business and put their names together to make the brand.

- Fulmers

Fulmer's Quality Lapidary Products, of Seattle, WA, made a 15" flat vibratory lap, and a larger one (18-20"), before going out of business.

- Gem-Lap

of Fennville, MI, made horizontal units with interchangable laps, and trim saws.

- Gemstone Equipment Manufacturing

GEM, 750 E. Easy St., Simi Valley, CA 93065, makes a drop trim saw. They also appear to make the Gy-Roc tumbler. I am told Tagit's son is now running the operation.

- Glen Engineering

af Everton Park, Australia made Topaz Tec faceting machines until they went out of business in 2003.

- Graves Co.

at 1800 Andrews Ave. Ext. North, Pompano Beach, Florida 33069 (800-327-9103) makes Mark faceting machines, lapidary equipment, and accessories.

- R & W Hall

at 57 Anderson Street, Cairns, Qld. 4870 Australia (61-7-4051-6672) makes Faceting machines and accessories.

- The HDM Manufacturing in E. Helena, MT (P.O. Box 931, 59635, 406-933-5737) makes the HDM Faceting Machine (aka, HDM Faceter), and lapidary equipment

- Highland Park was acquired by Contempo Lapidary around 1985.

Highland Park made combination lapidary units and saws.

- Hillquist Inc.

in Denver makes rock saws and thin section grinders. They used to make an arbor grinder.

- HiTech Diamond Products Inc. in Moorpark, CA, makes a complete line of lapidary machines and saws.

- H.O.P.E (Hiring Older People Enterprises)

of Riverside, California, made an outstanding chop style, preformer, trim saw in the mid to late 1970s that could also be used for carving.

- Imahashi Mfg. Co., Ltd.

at 533 Hino, Hino-shi, Tokyo, Japan (0425-82-1508) makes Faceting machines and accessories.

- Imperial Gem Instruments

at 2455 23rd Street, Santa Monica, CA 90405 (310-450-8725) makes Alpha Taurus faceting machines and accessories.

- Irv's Facet Machine

at 11907 E. Trent, Spokane, WA 99206 (509-924-5464) makes Irv's Facet Machine and accessories.

- Jarvi Tool Co.

at 780 East Debra Lane, Anaheim, California 92806 (714-774-9104) makes Facetron faceting machines and accessories, including a CNC model.

- John Lahr

at PO Box 94, Mt. Vernon, OH 43050 makes the Lap-Lap hand lapping device.

- Johnson Brothers Lapidary

in Orange, California has a complete line of lapidary equipment and supplies.

- S. E. Landon Company made the Slik tumbler in three sizes (tilted hexagonal barrel with open top, the small one was called the 'baby slik'), and a 14" slab/trim saw, in Joshua Tree, California from the late 1950's to the late 1960's. They also sold 'Slik' tumbling grits and polishes.

- Lapidary Arts

in Fresno, CA, made the Gem Master.

- Lapidary Hobby Crafts

made the Gemlap horizontal grinder/polisher.

- Lee Lapidaries, Inc.

at 3425 West 117th Street, Cleveland, Ohio 44111 (216-941-7458) makes the Lee Faceter faceting machine.

- Lortone

in Washington makes tumblers and a full line of lapidary equipment.

- Lux

in Idar Oberstein, Germany makes automated cabbing systems.

- LWD Engineering

at 56 Heysen St., Weston ACT 2611, Australia (02-6288-7752) makes the Drabsch faceting machine.

- Maxant Industries, Inc.

in Ayer, MA, made full lines of lapidary equipment, industrial sewing machines, honey processing equipment, and wax processing equipment. They made the old 'Bull Wheel' flat polisher from 1997 (when Ray Rock died) to 2007, when they focused on honey and wax processing, and sold their lapidary line to Polaris.

- MDR Manufacturing, Inc.

at P.O. Box 6951, Kingwood, TX 77325 (281-358-3027) makes MDR faceting machines and accessories.

- Millers Falls was acquired first by Ingersoll Rand and finally by the Gorilla Glue Company around 1950.

Millers Falls made grinding arbors (and a lot of other {power} tools, all highly valued by antique collectors now) beginning around 1868 before ceasing all operations after they were bought out.

- Nelson Machine Works out of Portland Oregon made Slab Saws, Rotary Laps, Grinders and Sanders. They advertised as makers of precision lapidary equipment in the 1940s and 1950s.

- O'Brien

O'Brien made a Faceting Machine.

- Poly

in Monrovia, California, made grinding units before going out of business.

- Polaris Tool and Machine

Polaris took over Rock's line (Bull Wheel, etc) from Maxant, and the Cab-O-Matic line, in 2007.

- Poly-Glo

Poly-Glo made "GEA TEC" multiple wheel (4") grinding units with changable (diamond?) grinding rings before going out of business. Poly-Glo appears to have been based in Germany.

- Poly-Metric Instruments, Inc.

at P.O. BOX 400, Clayton, WA 99110 (509-276-5565) makes Scintillator, Xristal-Tek, and O.M.F. faceting machines and accessories. The O.M.F machine is used to cut concave facets.

- Prismatic

made Faceting machines and heads.

- Raytech Industries, A Div. Of Lyman Products

at 475 Smith Street, Middletown, CT 06457 (800-243-7163), makes ultraviolet lights, diamond products and gem finishing equipment, Faceting machines and accessories, and metal finishing equipment.

- Richardson Rock Ranch makes a sander and a polisher.

- Roc

made automated cabbing systems.

- Rockette

of Denver, Colorado, made vibratory tumblers.

- Rock's of Texas was acquired by Maxant Industries, Inc. (978-772-0576) some years ago.

Rock's of Texas made multi-station cabbers, saw units, and combo saws with cabbers, and the bullwheel polisher.

- Rose Enterprises

made rociprolaps. They were acquired by Covington.

- Part of Scott-Murray was acquired by Diamond Pacific Tool Corporation (800-253-2954) some years ago.

- Part of Scott-Murray was acquired by Lortone (425-493-1600) some years ago.

- Sears Roebuck & Company

sold combo grinding units and flat laps under their own brand. These were believed to have been manufactured by Star Diamond.

- Shor International Corporation

at 20 Parkway West, Mt. Vernon, NY 10552 (914-667-1100) makes Shor faceting machines and accessories.

- Star Diamond was acquired by Barranca Diamond Products Inc. (310-532-5867) some years ago.

Star Diamond made combination lapidary units and small saws.

- Star Engineering, Inc.

in Moorhead, Minnesota, made combo grinding units.

- Stone Master

Stone Master in Kansas City, MO, made four wheel grinding units before going out of business.

- Tagit

in Pico Rivera, CA 90660, made the Gy-Roc line before turning it over to Gemstone Equipment Manufacturing. Johnson Brothers in Tarzana, CA was the dealer that handled the Tagit line.

- Ultra Tec Mfg., Inc.

at 1025 E. Chestnut Ave., Santa Ana, CA 92701 (714-542-0608) makes Ulta Pol and Ulta Tec faceting machines and accessories.

- Vermeer

makes heavy equipment and monster rock saws (rockwheels).

- VJ Engineering

at VJ Engineering, 200 Frenchville Road, Rockhampton NTH 4701, Australia (079-28-2119) makes the VJ faceting machine.

- Winter

in Idar Oberstein, Germany makes automated cabbing systems.

If you can help me identify or trace the history of other makers of lapidary equipment that are no longer in business (acquired or not, what they made, when, etc.) please let me know.

Commercial equipment is as much a part of our lapidary heritage as is homemade equipment and should not be forgotten. Most commercial equipment is prized, and passed on from lapidary to lapidary, often across generations.

And if I have missed any current manufactures, please send me details so I can add them too. I really would like to have links to all current lapidary equipment manufacturers.

You can return to The Tomaszewski Family Public Home Page, or visit my personal homepage for more Rockhounding information, or check out my collection of links for rockhounds, or read about Labeling and Cataloging Rocks, Minerals, and Fossils, or review some field trip reports, or view some specimens from my collection, or send me Email at Kreigh@Tomaszewski.net .